PRODUCTS | NECTOR

NECTOR 200

CONTROL PANEL FOR THE COMPLETE MANAGEMENT OF COLD ROOMS WITH INTEGRATED CONNECTIVITY

Control panel for the complete management of cold rooms with single-phase compressor up to 2HP with Datalogger function and integrated connectivity. Designed to integrate safety, protection, control and ease of installation into a single solution.

Applications

- Complete management of static or ventilated single-phase refrigeration systems up to 2HP, with off cycle or electric defrost, with direct compressor stop or pump-down in combination with the Datalogger / remote control function.

- Management of the single-phase evaporating unit only with freon solenoid valve consent and remote condensing unit consent in combination with the Datalogger / remote control function.

Main characteristics

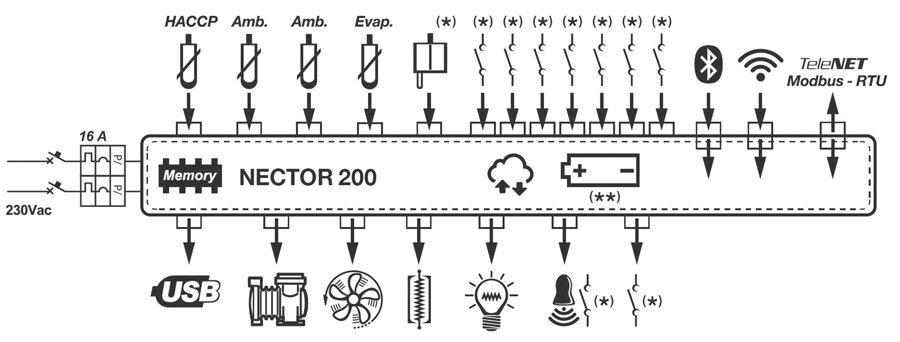

- Direct management of compressor, defrost heaters, evaporator fans and cold room light.

- Wi-Fi, Ethernet and Bluetooth (BLE) connectivity.

- Bluetooth functions with MyPego app: complete remote control of the instrument, configuration of connectivity settings, display of daily history and system status.

- Cloud functions with MyPego app (function can be activated by subscription): real-time system control; daily history; real-time alarm messaging notification.

- Integrated local webserver.

- Datalogger function with up to 2 years’ history.

- Humidification / dehumidification function with dedicated 4-20mA humidity probe.

- Condenser or evaporator fan speed management with 0-10V analogue output and dedicated pressure probe (probe not included).

- Off cycle, electric, hot gas and thermostat-controlled defrosting, also with real-time clock.

- Direct management of the solenoid valve for hot gas defrosting.

- Double evaporator management with dual end-ofdefrost probe.

- Emergency operation (in case of faulty ambient probe).

- Pump-down operation.

- Configurable cold/hot/neutral zone mode.

- Energy saving (day / night setpoint management, smart defrosts).

- Integrated USB port for datalogger / parameter download and software update.

- Backup battery for data logging in the absence of the main power supply (optional).

- 7 configurable digital inputs.

- 2 configurable digital outputs.

- RS485 for connection to the TeleNET or ModBUS supervision network.

Properties

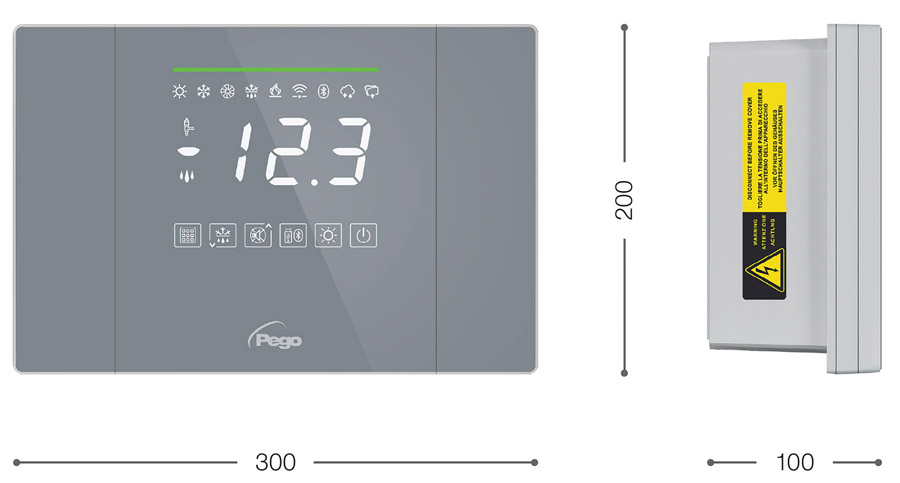

Dimension

NECTOR 200

300 x 200 x 100 mm

Front protection rating

NECTOR 200

IP 65

Insulation type

NECTOR 200

Class II

Working temperature

NECTOR 200

0 +50 °C

Relative ambient humidity

NECTOR 200

30% - 90% RH without condensate

Power frequency

NECTOR 200

50 / 60 Hz

Battery

NECTOR 200

12 V, NI-MH 1300 mAh, autonomy 40h (** optional )

General electrical protection (depending on the model)

NECTOR 200

Bipolar differential magnetothermal switch 16A, C-Char, ID=300mA

Connectable sensor types

NECTOR 200

Bipolar differential magnetothermal switch 16A, C-Char, ID=300mA

Resolution

NECTOR 200

Temperature: 0,1 °C

Humidity/Pressure : 1 RH% / 0,1 Bar

Humidity/Pressure : 1 RH% / 0,1 Bar

Read range

NECTOR 200

Temperature: -45 +99 °C

Humidity/Pressure: 0T 100 RH% / 0,1 Bar

Humidity/Pressure: 0T 100 RH% / 0,1 Bar

Configurable digital inputs

NECTOR 200

7

Normative referee

NECTOR 200

EN 12830

Adéquation

NECTOR 200

S (Conservation)

Type of climate environment

NECTOR 200

A

Accuracy class

NECTOR 200

1

Analogue outputs

NECTOR 200

0 – 10 V

RS485 Serial

NECTOR 200

Modbus-RTU / TeleNet

Bluetooth

NECTOR 200

Blue low energy

Wifi

NECTOR 200

802.11 B/G/N (2.4 GHZ) UP TO 150 Mbps

Ethernet

NECTOR 200

10/100 Mbps

Technical Characteristics

Ambient Condition

Electrical Characteristics

Inputs

Designation

Outputs

Connectivity

Dimensions and Diagram