The EasySteam OEM CCU sunk-electrode humidifiers series has been studied for obtaining the maximum in precision air conditioning applications (CCU – Close Control Unit).

The specifications that optimize it for this application are:

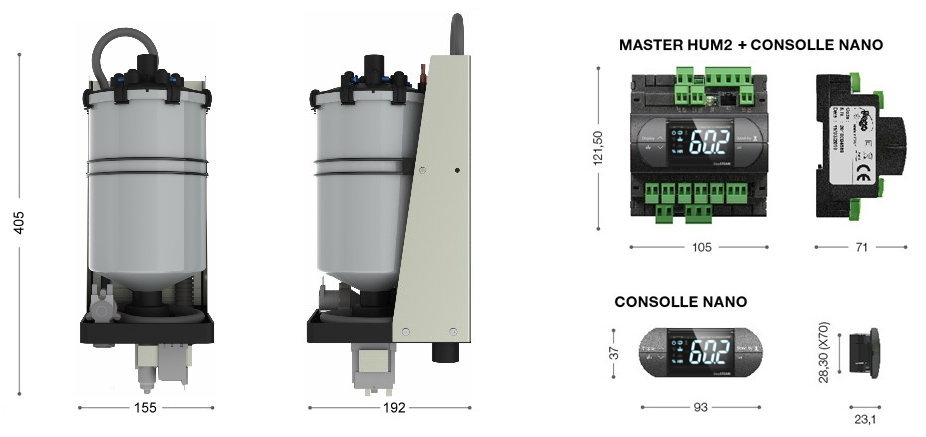

- Extra compact dimensions

- Modbus communication that can be easily interfaced with air conditioning controllers and systems

- Steel electrodes

- Drain pump

-

Steam/humidity generator for OEM applications suitable for housing inside air-conditioning machines.

-

Steam/humidity generator for OEM applications for industrial plants, offices, civil facilities, call centres, hotels, museums and bookshops, technological or medical facilities, tobacco industry, food industry, seasoning, wood industry, paper mills, printing industries and steam rooms.

- Compact kit with wall fixing plate for OEM application humidifying.

- Electrodes steam humidifiers.

- Single-phase power supply versions with steam producing up to 3 kg/h.

- Three-phase power supply versions with steam producing up to 6 kg/h.

-

Master/slave humidifiers management (up to 6 units) to reach steam productions up to 36 kg/h.

- Structure entirely of stainless steel.

- Easily interchangeable cylinders with steel electrodes, limestone filter on the bottom, maximum level sensor and connector connections.

- Solenoid valve for water charging.

- Tough and reliable drain pump.

- “Smart production for low conductivity” function; the humidifier automatically regulates the percentage of steam production based on the conductivity of the water.

- Available cylinders for low conductivity water (minimum conductivity limit 125 μs/cm).

- Separate electronic control for installation inside electrical panels and with integrated display (the display can be remoted with an optional kit).

- Management of second duct humidity probe to avoid condensation in the air duct.

-

Large accessories range.

- The kit does not include power contactor, terminals and wiring.

Featuring numerous parameters and an user-friendly display, the EASYSTEAM controller allows precise setting of humidifiers performance. Thanks to the high number of available variables it is possible to personalize humidifier functioning on the basis of customer requirements.

- Eight operating modes can be set among which ON/OFF from external contact, proportional with built-in humidistat and 4-20mA or 0-10V probe, proportional with external 0-10V signal. Built-in thermostat ON/OFF. BMS control via Modbus.

- Duct probe management.

-

Optimised use for steam baths thanks to the built-in temperature control, essence management, inlet and exhaust fan control.

-

Settable with maximum capacity.

-

Proportional regulation of steam dispensing from 20% to 100%.

-

Steam dispensing reduction from digital input.

-

Programmable automatic drainage when not used.

-

Management of up to 6 humidifiers in battery with master/slave configuration.

-

Humidifier operating hour meter.

-

Maximum level sensor management.

- Control console with large display and status icons for reading and programming work data remotely up to 100 m away with a simple phone cable.

-

Diagnostics for problems identifying or maintenance need.

- Serial RS485 connection with Modbus protocol.